REIMER/ ProAll Volumetric Concrete Mixers

L80-25

- 7.6 m3 production capacity

- 50 m3/hr production rate

- 5.7 m3 aggregate bin

- 4.4 m3 sand bin

- 2250 l water tank

- 3732 kg net weight – ALUMINIUM BODY

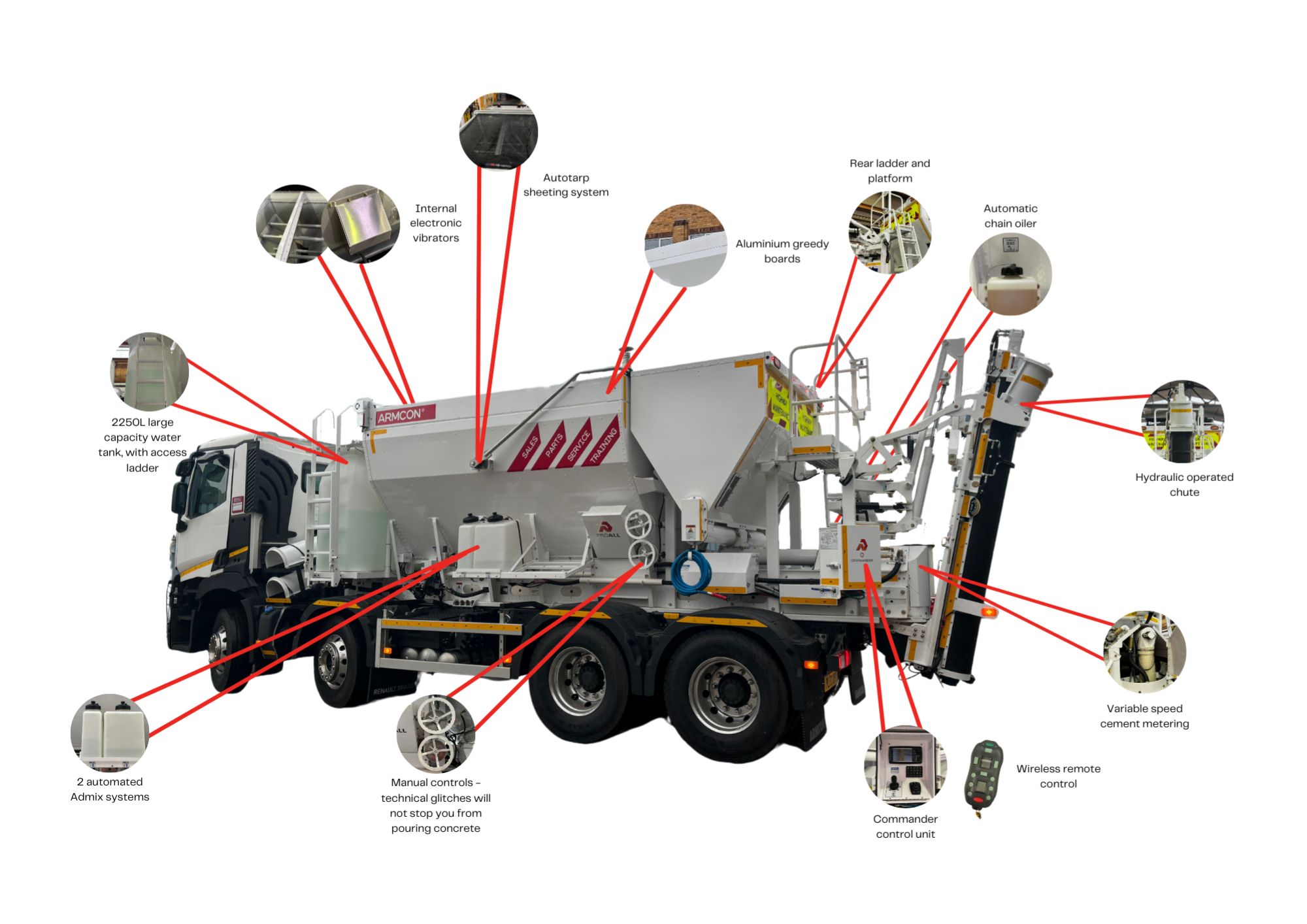

Body

- Aggregate Bin Liner

- 360°SwivelChute

- Aluminium Tool Box

- Aerator System for CementBin

- Aggregate Bin Extensions

- Pneumatic Fill

- Dual Water Tank Fill

- Fly Ash Bin

Safety

- Standard System Rear Ladder & Platform

- Cement Bin Safety Rail

Verification

- Belt Materials Sensors

- Gate Height

- Verification Sensors

- Load Cell System

Application

- Additional Vibrators

- Colour Feeder

- Fibre Feeder

- Gunite Auger

- Heat Exchanger

- Additional Admix Tanks

Additional

- Pressure Washer

- Custom Paint

- Extra Oil Cooler

- Auto-Lube System

Commander Control System

Automated control system for mobile concrete mixers offers the

following benefits:

Streamlined Operations: Eliminates the need for manual adjustments, saving time and effort during operations.

Real-timeInformation: Digital controls provide operators with immediate

feedback on the mixer’s performance, enabling precise adjustments.

User-friendly Interface: The control system features an intuitive interface for easy navigation and access to critical parameters.

Data-driven Improvement:The automated control system allows operators to analyse historical information and make data-driven improvements by storing and retrieving mixing data.

Enhanced Accuracy: The automated control system ensures precise control over critical parameters, producing consistent and high-quality concrete.

This automated control system optimises operations, provides real-time feedback offers a user-friendly interface, enables data-driven improvements,

and enhances accuracy for superior concrete production.

- 4 admix systems, 5 powder/auxiliary system capability

- Ability to set moisture contents

- Auger boom/ swing/ chute joystick

- Auto stow function

- Automated admix

- Automated water

- Automatic calculation of gate settings and ratios

- Calibration for aggregates and powders

- Data logging for thousands of previous mix jobs

- Digital adjustable auxiliary ratio for colour and flyash (up to 4)

- Digital adjustable cement ratio

- Digital adjustable vibrator times

- Digital auger and belt speed settings

- Digital production rate display(m3)

- Mix design loading and saving(up to 50)

- Printable receipts for last 25 jobs

- Selectable print options

- Volume stop feature

- Water set points adjusted on screen with changes in belt speed

- Water washout mode

Our Mixers Lineup

L60

- 6.1 m3 production capacity

- 50 m3/hr production rate

- 4.5 m3 aggregate bin

- 4.0 m3 sand bin

- 2.1 m3 cement bin

- 2250 l water tank

- 3403 kg net weight – ALUMINIUM BODY

L80-25

- 7.6 m3 production capacity

- 50 m3/hr production rate

- 5.7 m3 aggregate bin

- 4.4 m3 sand bin

- 2250 l water tank

- 3732 kg net weight – ALUMINIUM BODY

P85

- 7.6 m3 production capacity

- 50 m3/hr production rate

- 5.2 m3 aggregate bin

- 4.6 m3 sand bin

- 3.2 m3 cement bin

- 2250 l water tank

- 5180 kg net weight

P85 Precast Mixer

- 7.6 m3 production capacity

- 50 m3/hr production rate

- 5.2 m3 aggregate bin

- 4.6 m3 sand bin

- 3.2 m3 cement bin

- 2250 l water tank

- 5573 kg net weight

- 45 kW electric power pack

P95

- 9.2 m3 production capacity

- 50 m3/hr production rate

- 6.3 m3 aggregate bin

- 5.5 m3 sand bin

- 3.2 m3 cement bin

- 2250 l water tank

- 5502 kg net weight

P95 Trailer

- 9.2 m3 production capacity

- 50 m3/hr production rate

- 6.3 m3 aggregate bin

- 5.5 m3 sand bin

- 3.2 m3 cement bin

- 2250 l water tank

- 5502 kg net weight

- 56 kW Diesel power pack